Engineering unit

Aiming at acquiring required capabilities for design and manufacturing of new products and optimize them engineering department provides the company with:

1. Providing and documentation of technology, technical documents and required standards.

2. Designation and optimization of coefficient of process capabilities (CPK)

3. Designation and optimization of coefficient of machine capabilities (CMK)

4. Monitoring and management of production tools.

5. Monitoring and management of production and assembly fixtures.

6. Designation and monitoring of capabilities of gauges (CGK)

7. Monitoring and improvement of suppliers products quality by periodic assessment and introduction of suitable suggestion, if so required.

8. Layout design of the plant for optimizing the material flow of the production lines.

9. Feasibility study, design and preparation for prototype and pre launch production of the parts and/or components.

All above processes is organized through close cooperation and communication with other department of the company amongst which quality assurance (QA), production planning, production and commercial are noticeable.

Each engineering team is responsible for one or more of the following processes:

Product engineering unit

Preparation of product technical documents, dimensional and metallurgical and other related product testing standards.

Preparation and gathering of testing, replacement and material choice standards and instruction for controlling and acceptance of the factory incoming material.

Preparation of products bill of material (BOM) and parts lists, study the role of each part in final product and reliability and repair ability of parts according to customers objective and requirements.

Technical surveillance of material, part and component suppliers based on standards and instructions.

Designing and preparing of new product by reengineering.

Preparation , review and obtain an approval SQA from Sapco

Preparation and update direction in line with the IATF standard.

Providing and documentation of technical knowledge of gears and related information (catalogs standards)

Provide Summary sheet for setting Gleason machines.

Optimization and development of tooth profiles in order to increase safety factors and gears life and noise reduction.

Prototype and prelaunch production.

process engineering unit

With respect to quality management system establishment main activity of this sub department is based on advanced product quality planning as follows.

Capability study and provide the list of production equipment in order to establish of projects by industrial engineering.

Preparation of initial production processes, control plan documents, inspection instruction and PFMEA.

Preparation and design list of machineries, tools, fixtures, measuring and auxiliary tools by tooling and machinery engineering to design and produce procure them.

review and finalization of the documents related to production process , tools , machineries and equipment required for mass production

Assessment of production process capabilities(CPK) by statistical process control (SPC) analysis by quality assurance

Assessment of machinery capabilities (CMK) is also provided to monitor quality status and effectiveness of current machineries according to important parameters of product measurement on sample products received from quality assurance department.

Forming cross functional teams (CFT) of production and assembly processes related to ongoing projects.

process audit of production lines in order to prevent occurrence of a non conformity or correction of detected non conformity and cause of nonconformity in order to prevent recurrence and continual improvement of processes.

Compilation of J.S production lines for ongoing projects.

Providing and documentation of control plans, production processes, inspection instruction and PFMEA and capability assessment of production processes.

Production of prototype and pre launch production and review and finalizing the document of new gear production processes.

Industrial engineering unit

Based on advanced product quality planning and parallel with production and product engineering sub departments, industrial engineering performs the following activities.

Preparation of production operations flow charts and assembly process diagrams.

Preparation of operation time study , ergonomics study and methods of improvement.

Estimate calculation of production capabilities and required human resources.

Factory layout design and building specifications and dimension with respect to environment conditions.

Machineries and equipment layout and line bordering of production shops.

Planning product storage and handling through production lines and in stock.

Specifying the side equipment and facilities installation and required energy resources.

Packing and transportation design.

Cooperation with production and assembly processes audit teams.

Engineering project management and related periodical reports to the engineering manager.

In line with the product self-sufficiency the engineering section , takes action in localization office parts & motorcars and semi-heavy vehicles Axle complex , by benefiting the technical knowledge .that results , setting up the machining line , parts assembly, and the following mentioned complexes :

Peugeot and Samand group which has been reached in to mass production:

|

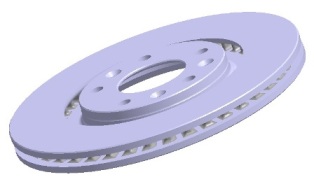

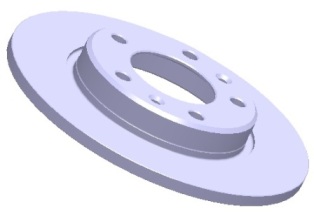

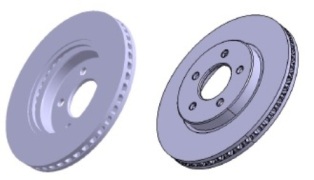

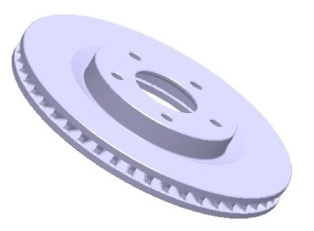

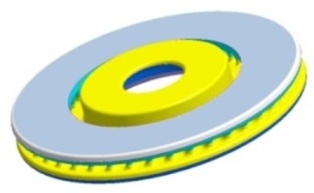

1.REAR BRAKE DISK 206

|

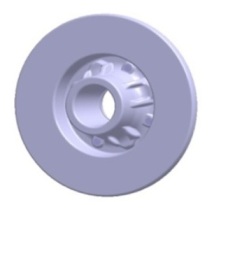

2-Drum 206

|

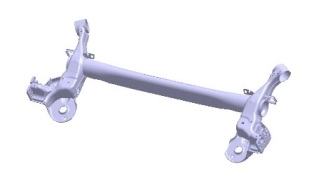

3- AXEL CROSSMEMBER BODY 206

|

|

|

|

|

| |

|

|

|

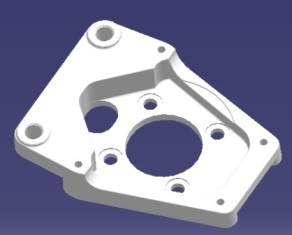

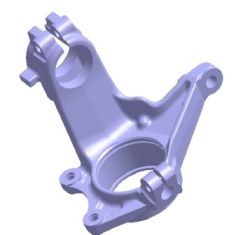

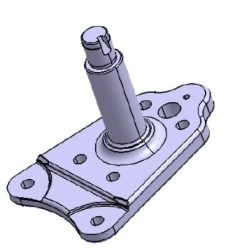

4-CALIPER SUPORT 206

|

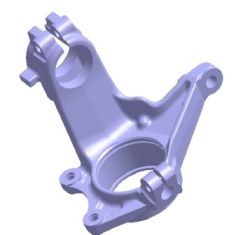

5-SUSPENTION ARM 206

|

6-CROSSMEMBER SUPORT 206

|

|

|

|

|

| |

|

|

|

7-WHEEL HUB 206

|

8-CALIPER SUPORT DENAPLUS

|

9-SUSPENTION ARM DENAPLUS

|

|

|

|

|

| |

|

|

| |

11- WHEEL HUB DENAPLUS

|

10-CROSSMEMBER SUPORT DENAPLUS

|

|

|

|

|

Projects underway include:

a) Peugeot and Samand group

|

1- FRONT BRAKE DISK

|

2- TORSION BAR 206

|

3- ANTIROLL BAR 206

|

|

|

|

|

| |

|

|

|

4-FRONT CALIPER 206

|

5-SHUCK ABSOEBER

|

6-SUSPENSION PIVOT

|

|

|

|

|

| |

|

|

|

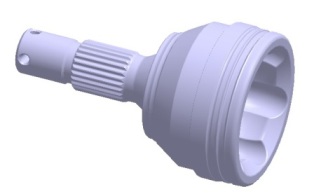

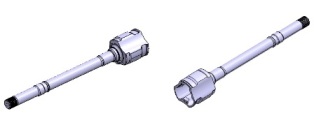

7- FRONT AXEL POLUS P206 ASSAY

|

8- FRONT BRAKE DISK DENAPLUS

|

9- REAR BRAKE DISK DENAPLUS

|

|

|

|

|

| |

|

|

|

|

|

10- SUSPENSION PIVOT DENAPLUS

|

|

|

|

|

b) H30 Cross Rear Axel parts

|

1-REAR BRAKE DISK

|

2-CALIPER SUPORT

|

3- CROSSMEMBER END PIECE

|

|

|

|

|

| |

|

|

|

4-AXEL ASSY

|

5-SUSPENSION ARM

|

6- RR AXEL CROSSMEMBER SUPPORT

|

|

|

|

| |

|

|

|

7-STUB AXEL

|

8- BODY CROSS PIPE

|

9- ANTIROLL BAR

|

|

|

|

|

| |

|

|

| |

|

10-TORSION BAR

|

| |

|

|

c) Haima parts

|

1-FRONT BRAKE DISK HAIMA S7

|

2-FRONT BRAKE DISK HAIMA S5

|

3- WHEEL BEARING HAIMA S7

|

|

|

|

| |

|

|

|

4-WHEEL BEARING HAIMA S5

|

5- SUSPENSION HAIMA S7

|

6- SUSPENSION HAIMA S5

|

|

|

|

| |

|

|

|

7-REAR BREAK DISK HAIMA S7

|

8- REAR BREAK DISK HAIMA S5

|

9-BEARING HUB HAIMA S7

|

| |

|

|

| |

|

|

| |

|

10-BEARING HUB HAIMA S5

|

| |

|

|

d) 301 Peugeot

|

1) REAR AXEL TOWIST BIM P301

|

2) REAR BRAKE DISK

|

3) REAR WHEEL HUB

|

|

|

|

|

| |

|

|

|

4) FRONT WHEEL HUB

|

5) FRONT BRAKE DISK

|

|

|

|

|

|

e) BEARING TEST LAB.PROJECT